Place of work: Dębica

Job description:

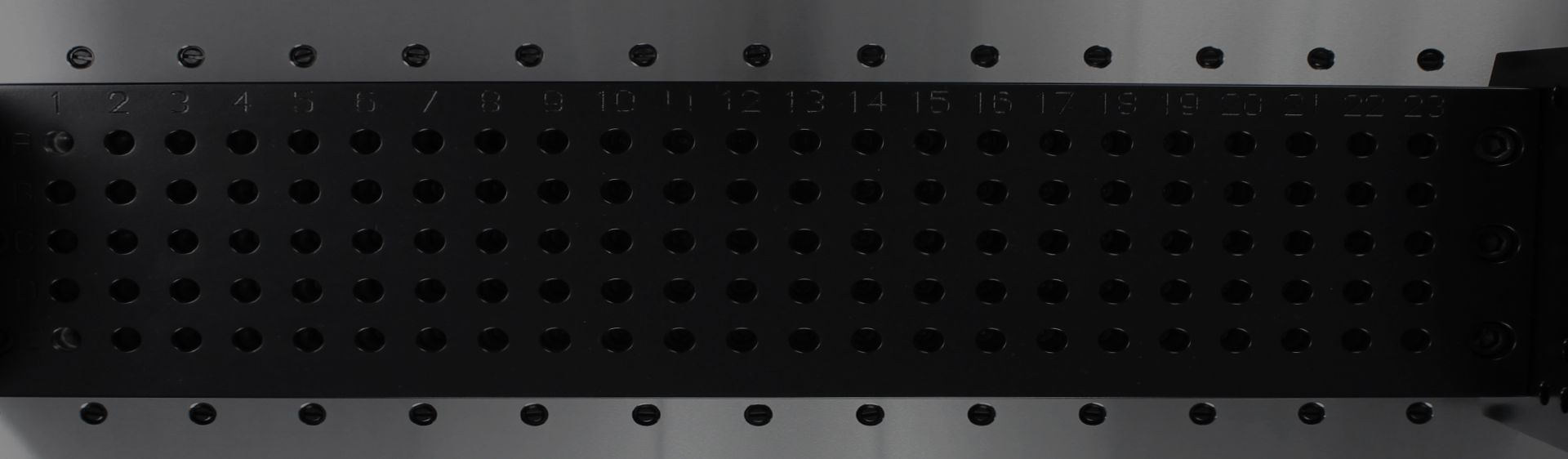

- setting and operating CNC machines 3,4,5-axis control Fanuc, Sinumeric 820

- implementation of the machining program on entrusted machines

- measurement of completed details at the workplace

- equipping the machine with the necessary tools

- care for maintaining the proper technical condition of the machine tool and tools

- precise workmanship with attention to the quality of work

Requirements:

- experience as a CNC operator – min 3 years

- knowledge of Fanuc, Sinumeric control

- good knowledge of technical drawings

- quality control of manufactured products with measuring tools

- knowledge of the basics of performance technology

- high quality of work, accuracy, reliability

- work in 2 shifts

- English language skills are welcome

- creativity, problem solving skills, analytical thinking

- care for order, cleanliness in the workplace

- compliance with applicable regulations, standards, technical and technological documentation

- ability to adapt to team work

We offer:

- work using very modern machines and tools

- gaining professional experience in the production of demanding details

- attractive employment conditions

- work in a growing company

- work from Monday to Friday in 2 shifts

- option of a long-term employment contract

- attractive remuneration conditions adequate to the skills and commitment to work

- development and professional development opportunities

Place of work: Dębica

Responsibilities:

- quality control of individual details during the production process, admission to production of implemented products

- keeping records related to quality control

- preparation of quality reports, inspection reports, as-built documentation, approval and execution of measurement reports

- cooperation with the technology department and the production department in solving quality problems

- writing programs for a measuring machine and confirming compliance of existing programs, program supervision

- detecting nonconformities and developing corrective actions together with the production and technology department

- preparation and supervision of sampling plans for details in the production process

- cooperation with the production and technology department in explaining customer complaints, solving quality problems for dedicated products and technological processes, developing and updating corrective actions

- supporting work in implementing and maintaining an integrated quality management system according to ISO 9001: 2009, ISO 14001: 2005, BS OHSAS 18001: 2007

- conducting analyzes and measurements of products and services in terms of quality standards required by customers based on the documentation provided

- monitoring compliance with quality standards in the Quality Control department

- analysis and monitoring of quality results of created products

- initiating and monitoring corrective actions and overseeing their implementation

- seeking areas and opportunities to improve quality

- initiation of technological corrections together with the technology and production department as well as post-inspection control

- ongoing supervision over quality and identification of parts put into production and their control during the production process

- supervision and record keeping of control and measuring equipment, maintenance supervision, calibration, legalization of instrumentation and measuring tools in KJ

- verification of the technical documentation of the detail before implementation into production in terms of having all the necessary features, dimensions, 3D models necessary to write measurement programs and prepare control and measurement documentation

- organizing a workplace, including compliance with health and safety, fire protection and environmental protection;

- checking compliance of the manufactured industrial product with the technical documentation;

Requirements:

- minimum secondary or higher technical education

- min. 2 years of experience as a Quality Controller – machining industry),

- English skills are welcome

- Ability to operate and write programs to a CMM measuring machine

- Ability to use contour, microscope

We offer:

- employment based on an employment contract on stable employment conditions, with real opportunities for raising professional qualifications and development within the company structures,

- work from Monday to Friday in 2 shifts

- remuneration adequate to your knowledge and experience,

- opportunity to develop, expand skills

Place of work: Dębica

Requirements:

- Minimum technical secondary education higher technical education

- Very good, practical, knowledge of technical drawing

- Welcome, additionally appreciated knowledge of English

- Experience in the CNC machining industry for a minimum of 5 years

- Minimum 3 years of work as a Technologist Programmer after a minimum of 1 year of work as a CNC operator

- Minimum 3 years of writing programs in GibbsCam or NX 10, 11

- Experience 2 years working at Solidworks

- Ability to creative, analytical thinking, constructing, designing new solutions

- Creativity, ability to solve problems

Responsibilities:

- Writing programs for CNC machines 3,4,5 axis milling machines, lathes, grinders

- Development of new parts production technology

- Preparation of technological documentation for products ordered for production

- Design and selection of appropriate tools and technological equipment for production processes

- Performing technological supervision over manufactured products and optimizing the technological process;

- Verifying documentation in terms of its correctness, technological possibilities of making details and suggesting changes

- Creating production documentation production guides, processing instructions, sampling plans, measurement plans between operational, co-creating tool data management system – Tool Data Management

- Solving technological problems and coordinating activities related to current production;

- Supervising the quality of manufactured details and the reasons for the occurrence of deficiencies, and developing corrective and corrective actions to prevent non-compliance;

- Supervision of technological and production documentation;

- Conducting electronic data archiving;

- Cost estimation of details and analysis of the technology of manufactured parts in order to reduce production costs;

- Cooperation with the quality control department and the production department in ensuring the implementation of details in accordance with the requirements of technological documentation;

- Cooperation with the production and quality department in the process of implementing new parts and mass production

- Making corrections in programs during the implementation of details.

- Cooperation with all departments in order to comply with the Management Systems (ISO) in force in the plant and their development and improvement;

- Establishing a technology department’s work schedule and ensuring timely execution

We offer:

- very good working conditions

- work in a dynamically developing company

- working with high quality products that require creativity, thinking

- work on an inspiring team of specialists

- opportunity to develop and improve skills

- necessary, very good, modern work tools

- work from Monday to Friday in 1 shift system

- attractive remuneration conditions adequate to the skills and commitment to work